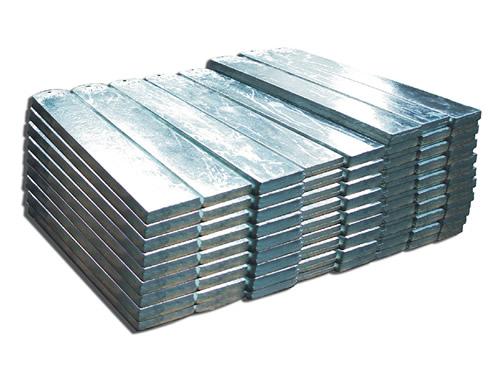

Aluminum Ingot

Ordinary industrial pure aluminum is thought as 1000 series aluminum ingot, aluminum content upto 99.0%. Low strength, heat treatment can't be further strengthened; But it is very malleable. Aluminum products have good corrosion resistance and weldability; After anodic oxidation, thecorrosion resistance of aluminum ingot are often improved, and a more beautiful surface layer can beobtained.

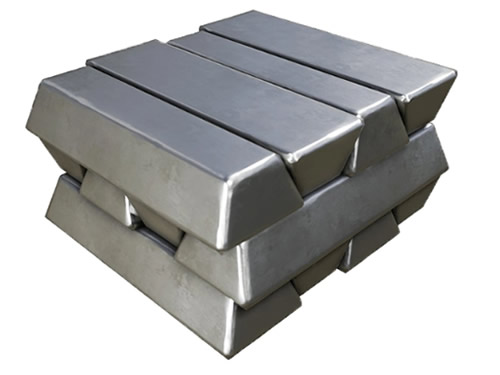

99.95% Zinc Ingot

Zinc ingot is a metallic product that is primarily composed of pure zinc or high-purity zinc alloys. It is commonly found in the form of solid blocks or cylindrical shapes. It is used in the production of galvanized steel, anti-corrosion materials, electronic components, batteries, zinc alloys, and as an additive in metallurgical processes. Its versatility and favorable properties make zinc ingot a valuable metal material for numerous industrial and commercial uses.

Special High-grade(SHG) Zinc Ingot

Special High-grade (SHG) Zinc Ingot refers to a specific grade of zinc ingot that is recognized for its high purity and quality. SHG zinc ingots are produced using a specific refining process that ensures a minimum zinc purity level of 99.995%. This high level of purity makes SHG zinc ingots suitable for applications that require exceptional corrosion resistance and superior electrical conductivity.

A7 A8 A9 Aluminum Ingots

A7, A8, A9 aluminum ingots are internationally recognized grades used to differentiate aluminum materials with different purities and compositions.

High grade 99.995%(HG) Zinc Ingots

High-grade 99.995% zinc ingots refer to a specific grade of zinc ingot that possesses an exceptionally high level of purity. These ingots are composed of at least 99.995% pure zinc, with very low levels of impurities.

High Purity Lead Ingots

Lead ingot is a solid metallic block composed of high-purity lead, commonly used in various industries for its malleability, corrosion resistance, and electrical conductivity.

High Quality Tin Ingots 99.99%

Tin ingot is a solid metallic block with a silver-white appearance and a smooth surface. It is composed of high-purity tin, typically exhibiting a uniform structure and tightly packed grains. Tin ingot has a relatively low density and melting point, making it widely used in applications such as soldering, electronics manufacturing, alloy preparation, and food packaging.

Pure Tin Metal Ingots

They are produced by refining tin ore to remove impurities, resulting in a high-purity tin product. These ingots are characterized by their silver-white color and smooth surface. They are composed of almost entirely tin, with minimal trace elements or impurities.

Pure Magnesium Ingots

Magnesium ingots are a common metal material that typically exist in solid form. It has lightweight, high strength, and good corrosion resistance, making it widely used in multiple fields.

Magnesium Alloy Ingots AZ31B/AZ91D/AM50

Magnesium alloy ingots refer to solid blocks or bars of magnesium-based alloys. These ingots are produced through the casting or solidification of molten magnesium alloy, typically in a controlled environment.